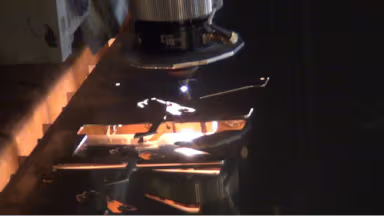

Laser Cutting

Custom Laser Cutting with our 1 of our 2 Cincinnati 6 Foot x 12 Foot Tables

Welding is a fabrication process that joins metals by causing coalescence. Coalescence's definition is: To join into a single mass or whole. Here at ACU, we are dominate in the restaurant and bar industry. In this industry, our products are viewed by thousands on a daily basis. When thousands view a product, people notice our quality because of the welding (bonding process) that makes our product quality stand out from the rest.

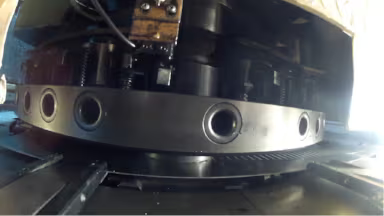

High Speed Punching

High speed punching machine - Strippit Turret Punch Center - (33 station with auto indexing)

We offer you the fastest high speed metal punching and stamping available. Our Strippit Turret Punch Center is the most productive punching machines available, providing an economical solution and timely delivery of high volume metal parts. Forming, counter sinking, counter boring, and tapping capabilities are available with various tooling options.

ACU Precision Sheet Metal's high speed sheet metal punching solutions provide an uncompromisable level of speed and efficiency for today’s most demanding markets. Standard and other various punch and stamp tooling are kept on hand. Custom tooling can be configured for your specific job.

Metal Forming in a Press Brake

Cincinnati Press Brakes

Bending is a metal forming process in which a force is applied to a piece of sheet metal, causing it to bend at an angle and form the desired shape. A bending operation causes deformation along one axis, but a sequence of several different operations can be performed to create a complex part. Bent parts can be quite small, such as a bracket, or up to 10 feet piece of metal

Precision Mig and TIG Welding

Precision Mig and TIG Welding

Welding is a fabrication process that joins metals by causing coalescence. Coalescence's definition is: To join into a single mass or whole. Here at ACU, we are dominate in the restaurant and bar industry. In this industry, our products are viewed by thousands on a daily basis. When thousands view a product, people notice our quality because of the welding (bonding process) that makes our product quality stand out from the rest.

Some of our sheet metal machinery...

(2) CNC Cincinnati Lasers 6 Foot x 12 Foot Table

Strippit Turret Punch Center

(33 station with auto indexing)

Two (2) Cincinnati CB II Press Brake 90 ton 10’

Lincoln Power 215 MIG Welder

Stud Welder and Spot Welder

Edwards 55 TON Iron Worker

Cincinnati CB II Press Brake 60 ton 6’

Cincinnati 250 Hydraulic Power ¼” Shear

Euromac Hydraulic Notcher

Haberle H350 Cold Saw

Miller 210 Millermatic MIG Welder

Nine (9) Baldor Grinder’s and Polishing Motor’s

36” Power Roll

Lincoln Airline Electric Power Seam Welder

Six (6) Lincoln Wave TIG 275 Welders

Lincoln Power 215 MIG Welder

Thermal Dynamics Plasma Cutter

Rutland 16” Wet Band Saw

Big Brute Pipe and Tube Bender